The Silence is Over. Now the Race Begins.

Let me be honest with you. I’ve been navigating the Chinese manufacturing landscape for over 20 years, and every year, the weeks following Chinese New Year (CNY) feel like the same chaotic movie.

Right now, your inbox is probably quiet. But inside the industrial zones of Guangdong, Zhejiang, and Fujian, the gates are unlocking.

If you are a brand owner in North America or Northern Europe, you are likely sitting on pins and needles, wondering: “When will my goods actually ship?” or “Did I miss the boat for Summer 2026?”

This isn’t just about unlocking doors; it’s about ramp-up time. Today, I’m going to pull back the curtain on the Post-CNY Factory Recovery, give you a tactical guide on securing your SS26 inventory (yes, we are talking about those trending Capri pants and platform sandals), and explain why the smartest players are already talking to me about Christmas.

Trend 1: The Truth About Post-CNY Factory Recovery

(China factory reopening dates 2026, production lead time February)

Many buyers assume that if a factory says they reopen on February 18th, production starts at 100% capacity on February 18th.

This is the biggest misconception in sourcing.

The “Worker Return Rate” Reality

In reality, a factory might “open” with only administrative staff and 30% of the line workers. The skilled sewers and technicians often trickle back over two weeks.

If you are sourcing complex items, like a Long Sleeve Sheer Top Layering Bulk order or intricate Custom Printed Mesh Fabric, quality consistency is risky during these first 10 days. The team is rusty, or new workers are filling seats.

How to “Push” Your Order Without Being Annoying

I see clients panic and send daily emails: “SHIP NOW!” This gets you nowhere. Here is the veteran approach:

- Don’t ask “When will it be done?” Instead, ask: “What is the current worker return rate on Line 3?” or “Has the raw material for my Low MOQ Organza Dress arrived at the warehouse yet?”

- Focus on Material Status. Production cannot start without fabric. Confirming that your Sheer Clothing Manufacturer has the fabric in hand is 90% of the battle.

Pro Tip: Ordering now (mid-February) is smarter than waiting until March. By March, the “wait-and-see” crowd will flood the factories, and lead times will double. Get in the queue while the line is forming, not when it’s out the door.

The “Real” Reopening Timeline: Week by Week

To help you manage expectations, here is the realistic breakdown of what happens inside a factory post-CNY. This is based on data from over 500 factory visits in my career.

- Week 1 (Feb 18 – Feb 24): The “Skeleton Crew” Phase.

- Status: Admin and sales are back. Machines are being recalibrated.

- Worker Rate: 20-30%.

- Risk: Do not push for “Mass Production” start here. The few workers present are often fixing maintenance issues. If you force production now, defect rates on Custom Printed Mesh Fabric will spike because the color-mixing technicians haven’t returned yet.

- Action: Finalize your tech packs and confirm raw material arrival.

- Week 2 (Feb 25 – Mar 3): The “Warm Up” Phase.

- Status: Production lines start moving at half speed.

- Worker Rate: 50-65%.

- Risk: This is when “worker churn” becomes visible. Factories realize some skilled sewers aren’t coming back. They start scrambling to hire new hands.

- Action: If you have a Low MOQ Organza Dress order, ask for photos of the first output off the line. Inspect the stitching closely. New workers often struggle with slippery fabrics like organza.

- Week 3 (Mar 4 onwards): The “Full Throttle” Phase.

- Status: Capacity hits 90%+.

- Risk: The backlog from pre-CNY orders creates a bottleneck.

- Action: This is where having a local agent (like V7prox) pays off. We physically stand on the line to ensure your order isn’t pushed behind a bigger client’s order.

Trend 2: SS26 Final Call – Micro-Trends You Can Still Catch

(Ready to ship summer clothing, sunglasses supplier China)

If you realized you are short on stock for Spring/Summer 2026, you are not alone. We are seeing a massive surge in “chase orders” .

The key here is speed. You do not have time for 60-day development cycles. You need factories with ready fabric or open molds.

Finding a factory is simple. But finding one that understands quality is hard. Here are the specific categories and material specs you must check for your SS26 orders.

1. The “Sheer” Trend (Layering & Mesh)

Are you sourcing Long Sleeve Sheer Top Layering Bulk orders? You must be careful.

The biggest customer complaint is “itchiness.” This happens when factories use cheap polyester mesh.

- Our Advice: Use a 95% Nylon / 5% Spandex blend. Make sure it has a “soft-touch” finish.

- Printing Tips: You need to check your Custom Printed Mesh Fabric Supplier. Ask them: “Do you use digital printing?”

- Why? Old screen printing blocks the mesh holes. This ruins the fabric. Digital printing keeps it soft.

- MOQ: Look for a Low MOQ Organza Dress factory that stocks “market fabric.” This allows you to order smaller quantities.

2. The Capri Pants Revival

Capri pants are back. But there are two different styles. You need to pick the right one.

Style A: The Denim Look Are you looking for a Y2K Denim Capri Pants Supplier?

- The Fabric: Ask for “non-stretch” denim. Or use a “1% elastane” blend.

- The Wash: Request a “dirty wash” or vintage tint. This is the authentic Y2K look Gen Z wants.

- Inclusivity: Demand for a reliable Plus Size Capri Pants Factory is outpacing supply. Make sure your supplier has the right grading for larger sizes.

Style B: The Yoga Look Demand is huge for Private Label Yoga Capris No Front Seam.

- The Fabric: You need “Double-knit Interlock” fabric.

- The Weight: We recommend Nylon/Lycra (220gsm+).

- The Risk: Single-knit fabric is too thin. It will be see-through when you bend over. Do not accept this.

- Athleisure Basics: This same rule applies if you are sourcing a Cropped Leggings Manufacturer or looking for High Waisted Capris Bulk.

3. Footwear: Comfort is Key

Footwear molds take time. For SS26, focus on molds that are ready to go.

Chunky Flip Flops Are you talking to an EVA Slippers Factory China? You must ask about the “Expansion Ratio.”

- Too Hard: The shoes will hurt.

- Too Soft: They will flatten in a week.

- The Sweet Spot: We test for “Shore C 45-50”. This gives you that popular Soft Cloud Slippers Bulk Buy feeling.

- The Trend: Look for Chunky Flip Flops Wholesale options with thick soles (4cm+).

Platform Sandals If you are buying Custom Logo Platform Slides, pay attention to the mold.

- The Rule: Ensure the logo is “embossed.”

- The Warning: Do not just print the logo on top. Printed logos rub off easily. Embossed logos last forever.

- Niche Styles: We are also seeing high demand for Y2K Thong Sandals Supplier contacts and Platform Sandals Manufacturer options that offer bright, neon colors.

- Startups: If you are new, finding Custom Logo Platform Slides Low MOQ is crucial. We can help you find factories that accept 500 pairs instead of 5000.

Sourcing Strategy: For these categories, do not develop custom fabrics. Ask us to find factories with “stock fabric” in trending colors. This cuts 20 days off your lead time.

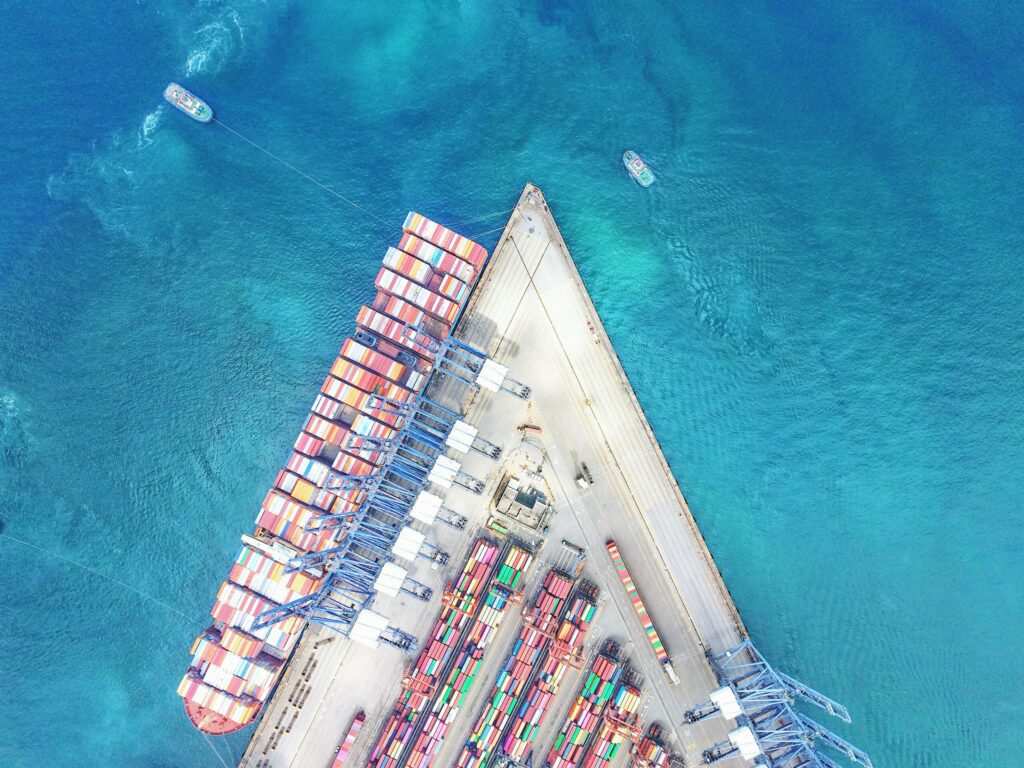

Trend 3: Navigating The Freight Waves

(China to US North America shipping rates February 2026, freight forwarder China recommendations)

Cost & Freight Updates are the headache no one wants but everyone has to deal with.

Post-CNY, shipping demand usually dips slightly for two weeks (the lull) and then explodes in March.

- The Lull (Late Feb): This is your window. If you have goods ready, ship them now.

- The Spike (Mid-March): As all the delayed factory orders finish, they hit the ports simultaneously.

We are currently advising clients to lock in specific China to US shipping rates February 2026 contracts now, rather than playing the spot market in March.

Logistics Strategy: Air vs. Sea vs. Fast Boat

With China to US shipping rates February 2026 fluctuating, you need a mixed strategy. Don’t put all your eggs in one container.

- Option A: The “Emergency” Air Freight (3-5 Days)

- Best for: 10% of your stock (e.g., the first batch of Trending Y2K Fashion Supply to capture the early trend).

- Cost: High, but guarantees you are first to market.

- Option B: The “Mason/Matson” Fast Boat (12-14 Days to West Coast)

- Best for: Restocking High Waisted Capris Bulk.

- Cost: A middle ground. Faster than regular sea, cheaper than air. This is the secret weapon for Amazon sellers.

- Option C: Regular Sea Freight (30-45 Days)

- Best for: Your Q4 Christmas Decor orders.

- Cost: Lowest. But you must book 3 weeks in advance post-CNY.

As your freight forwarder China recommendations partner, V7prox often splits shipments: send 200 units by air to start selling, and 5000 units by sea to replenish stock.

The Counter-Intuitive Strategy: Why You Should Talk About Christmas Now

(Holiday inventory planning, custom packaging manufacturing)

This might sound crazy while we are discussing summer sandals, but hear me out.

Sourcing for Q4 Starts Now.

Why? Because of Supply Chain Congestion. Last year, brands that waited until June/July to book their Christmas Decor/Gifts production faced:

- Higher raw material costs.

- factories rejecting orders due to capacity.

- Insane peak-season shipping surcharges.

The “Smart Brand” Timeline:

- February/March: Finalize designs for Holiday collections. Start discussions for Trending Y2K Fashion Supplyfor winter party wear.

- April: Sample approval.

- May: Place bulk orders.

- August: Goods ship.

- October: Goods are in your warehouse, ready for Black Friday.

By shifting your calendar, you avoid the China supply chain update nightmares that happen every Q3. You get better pricing because factories are “hungry” for future orders right now.

Why You Can’t Do This Alone

You can read all the lead time strategy guides in the world, but when a factory manager stops replying on Email because he’s short-staffed, you are stuck.

Sourcing isn’t just about finding a supplier on Alibaba; it’s about execution. It’s about having someone on the ground who can walk into that Low MOQ Organza Dress Factory and verify if the fabric is actually there. It’s about having a partner who knows which Platform Sandals Manufacturer has open capacity today.

At V7prox, we don’t just forward emails. We are your supply chain department in China. We manage the recovery chaos, we expedite the SS26 rush, and we help you plan Q4 while your competitors are still sleeping.

Ready to secure your supply chain for 2026? Don’t let the factory reopening chaos derail your year. [Book a Free Sourcing Strategy Call with us] today, and let’s get your production moving.

Frequently Asked Questions (FAQ) about Post-CNY Sourcing

Q: Can I still manufacture custom fabrics for SS26 delivery?

A: Honestly? It’s risky. Developing a Custom Printed Mesh Fabric from scratch takes 25 days for lab dips and strikes-offs. Added to production time, you might miss the summer window. We recommend using “market stock” fabrics for speed.

Q: What is the Minimum Order Quantity (MOQ) for these trending items?

A: It depends. A Low MOQ Organza Dress Factory might accept 100 pieces per color if using stock fabric. However, for Private Label Yoga Capris with custom colors, factories usually demand 500+ pieces because of the dyeing vat size.

Q: How do I avoid “bait and switch” quality after Chinese New Year?

A: This is common when factories use temporary workers. The only solution is a During-Production Inspection (DUPRO). Don’t wait until the goods are packed. Send V7prox in when 20% of the goods are made. If there are stitching issues on your Cropped Leggings, we catch them before 5000 pairs are ruined.